The International Association of Optics and Photonics, SPIE publishes an article on tactile sensors and «electronic skin». These are made of 2D materials and could be used in the body to allow continuous monitoring of movement. smartLIGHTING offers a summary of the most important aspects of the article, authored by Jong-Hyun Ahn (University of Seoul, Korea).

2D materials that include mechanical and optical properties may also exhibit different characteristics: thus each material, depending on its electronic structure, can be described as semi-metal, semiconductor, or insulator.

Graphene, for example, has semi-metallic properties, and can be used for transparent electrodes.

Sensors in the human body

A potential application of these materials in 2D is to turn them into flexible and portable tactile sensors. When added to the skin, they would allow devices monitor health. So far, however, limitations in sensitivity and mechanical flexibility of the materials have hindered the development of portable tactile sensors for direct integration on human skin or fabric.

Finding a new sensor

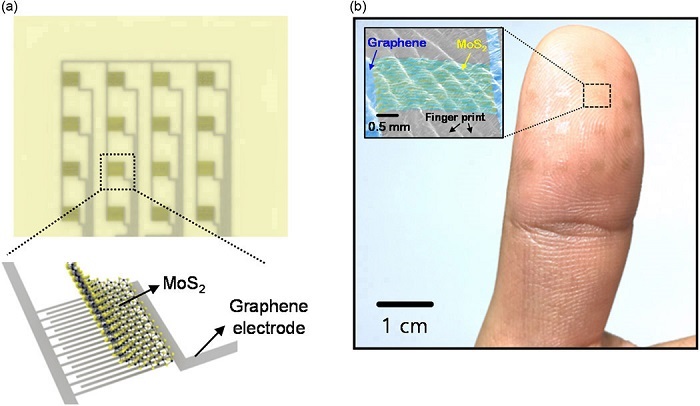

To overcome these limitations, a flexible tactile sensor, based on 2D materials has been developed for use next to the skin using a molybdenum disulfide semiconductor as a strain sensor and graphene as a transparent electrode. Both 2D materials have great mechanical flexibility and optical transmittance. In addition, molybdenum disulfide semiconductors exhibit high sensitivity and reliability for the sensor channel, and graphene electrodes have good contact properties and conductivity.

A chemical vapor deposition technique to synthesize high-quality, large-area molybdenum disulfide and graphene was used to produce a 2D material-based tactile sensor.

The researches have been able to prove the applicability of 2D materials in tactile sensors and electronic skin that can be worn on the body to monitor motion. They used conformal contact to fabricate wearable devices for use on the fingertip. These devices showed good output characteristics (sensitivity and repeatability) for wearable sensors, providing a new route to the development of wearable applications, such as E-skin.

Next steps

In future work, the team will seek to address critical challenges to the application of these sensors, such as ensuring the production of high-quality 2D materials and new device architectures.

The full article can be read in the SPIE website