LG Display announced that the company started mass production at its new Gen 5 OLED light panel production line in Gumi, Korea and launched its new OLED light brand, Luflex. With these moves, the company will lead the lighting market, providing a powerful boost to the nascent sector globally.

The Gen 5 line (1,100mm x 1,250mm) initially produces 15,000 sheets per month, which is about a 30fold increase as compared to the previous Gen 2 line (370mm x 470mm) with monthly capacity of 4,000 sheets. The production capacity will be gradually ramped up.

“LG Display’s step to start mass production at the new line marks a significant turning point in the lighting industry,” said Sung Soo Park, Vice President and Head of the OLED Light Business Division at LG Display. “We expect that this will improve the price-competitiveness of OLED light technology which in turn will trigger widespread adoption of OLED lighting around the world.”

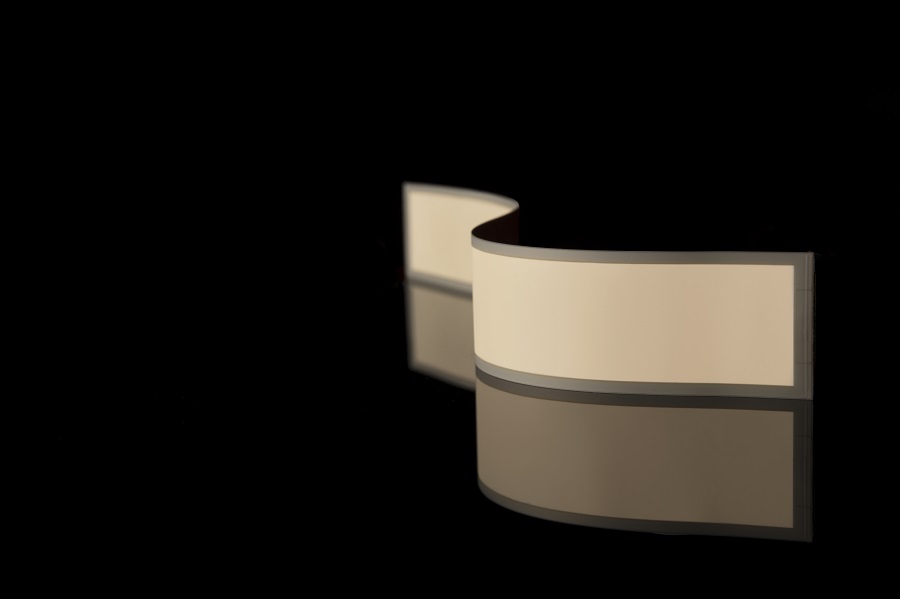

LG Display also unveiled its new Luflex brand for the company’s OLED light panels. Luflex is a portmanteau of “lux” (light in Latin) and “flexibility,” reflecting a core characteristic of OLED lighting – that it is flexible, bendable and rollable, making it highly design-friendly. It is also a value creator that offers a premium sense by converging naturally into various applications, such as mirrors and furniture.

“The launch of the new brand along with the expanded production at the new line reflects our belief that OLED lighting has unlimited potential and it demonstrates our commitment to lead the market,” said Park. “We are confident that Luflex will become a representative brand in the OLED lighting industry.”

OLED light panels offer high commercial potential for lighting manufacturers. As a lighting solution, OLED is easier on the eyes than conventional sources such as fluorescent and LED, as it is very close to sunlight and offers great uniformity in its luminescence. It is virtually heatless, meaning that it can be used to illuminate, for example, food displays or antique wooden furniture or buildings.

At just 0.41mm thick, OLED light panels are super slim and their flexibility means that they can be creatively shaped into curves or spirals – an attribute impossible before, and which cannot be done with other light sources. OLED lighting panels have already been adopted for experimental applications by world-famous industrial designers including Ron Arad and Ross Lovegrove. Customers have commented that OLED lighting installations, beyond providing simple illumination, can actually improve the attractiveness of spaces.

LG Display has started mass production of OLED tail lights for automobiles, which has drawn attention from global automakers and tier-1 component companies. In the case of general OLED lights, the company has established various installations in hotels, retail spaces, food and beverage outlets, universities, etc., and more and more customers are making inquiries after seeing these projects. The overall market environment is turning more and more positive and encouraging towards OLED lights.

According to ID Tech Ex, a market research firm, the global OLED light panel market is expected to grow at 52% CAGR over the next decade and will expand in value to USD2.2 billion in 2026.